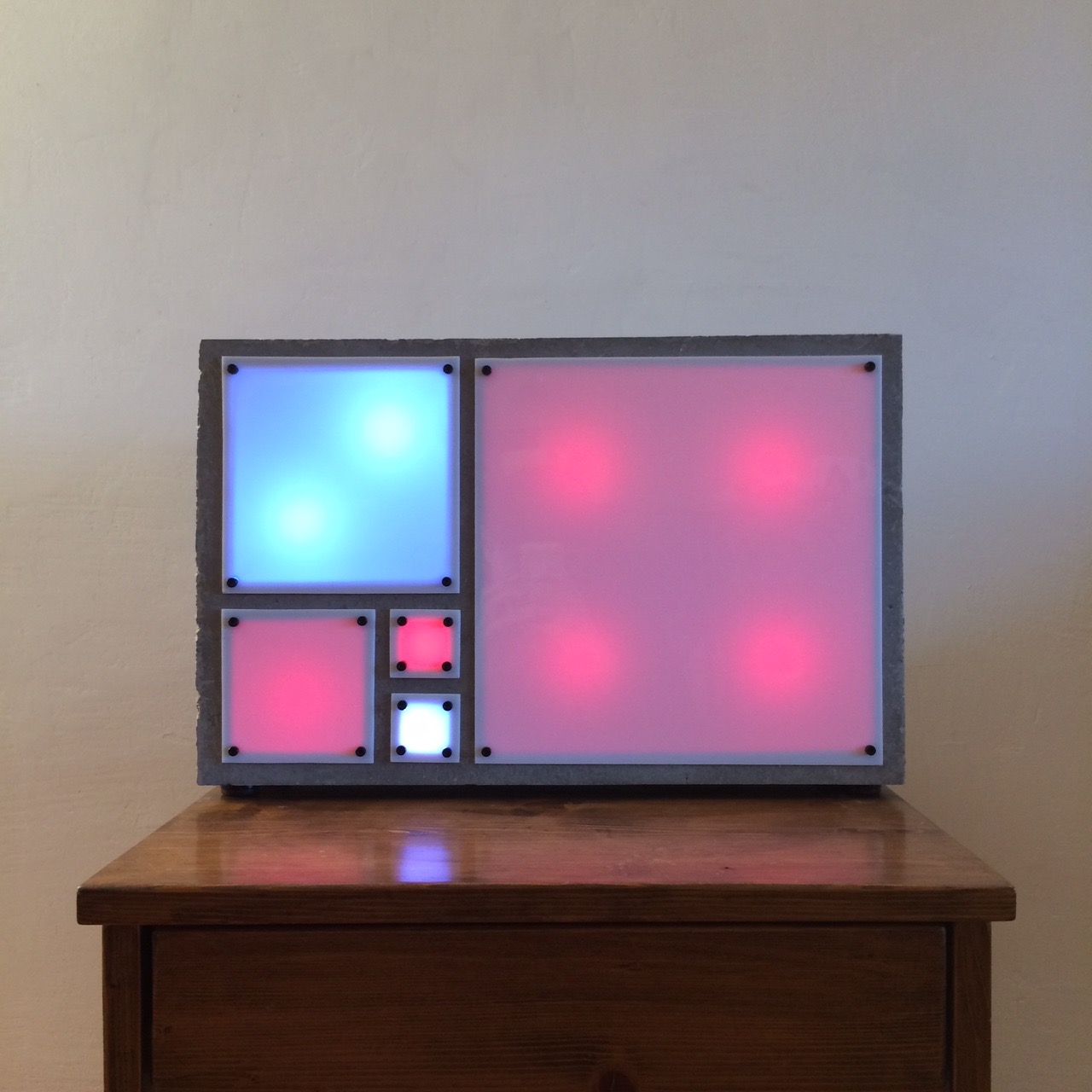

Making a concrete fibonacci clock

The idea of the Fibonacci clock is a brainchild of Philippe Chrétien, who calls his creation “a clock for nerds with style”. It’s certainly not a very practical clock, but the fusion of the curious numerical sequence with a lighting installation aesthetic is just too appealing to look away.

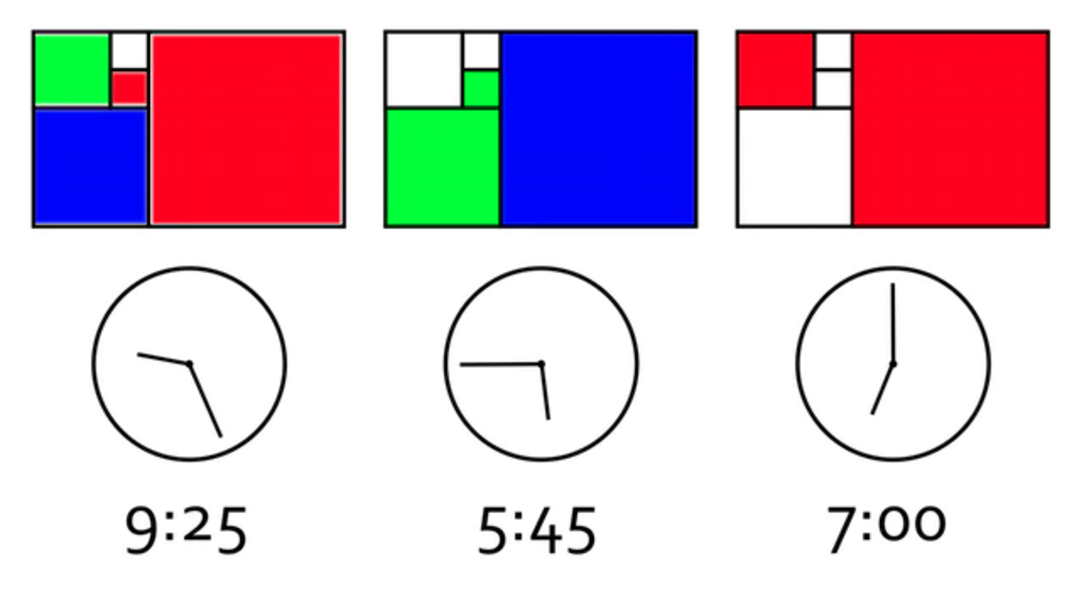

To tell the time on this timepiece, you need to use some brains. There’s an equation (check out this link for more details) where you use numbers related to which chamber is lit with which color. Here’s an example:

Phillipe is offering finished products in pretty wooden casings, but I needed to add one extra dimension: brutality. Let’s make this thing out of concrete! I purchased the electronics part (LEDs and the controller) only, and used them for my interpretation of the clock.

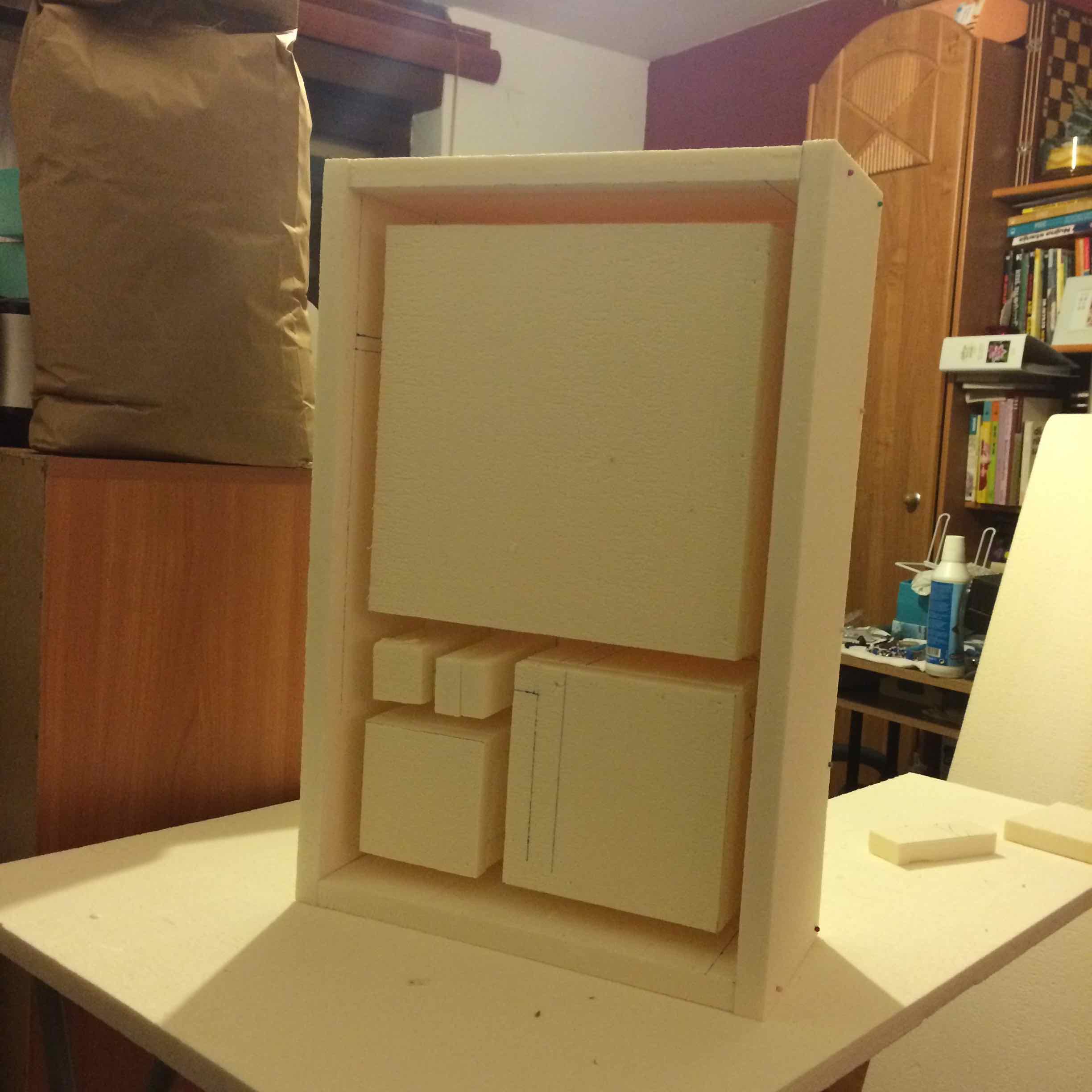

Make a mold

For molding of my concrete projects I often use Styrodur (a brand of extruded polystyrene) which I find to be the perfect tradeoff between the ease of handling and rigidness for holding shape (for smaller objects at least). The pieces are glued together.

Pour the concrete into the mold

I use a mixture of standard cement, sand, water. Adding reinforcement is crucial, otherwise the concrete brick falls apart and cracks. In this case I used glass fiber, but I’m regretting it, because the fibers make the the surface of the concrete look bad (tiny stripes and scars). I should have just used good old steel reinforcement.

This amount of concrete is surprisingly heavy (weight of a small child), and somehow I didn’t fully account for that during the process. As I was pouring the concrete in the mold, the outer walls started to bend. Yikes! I needed a quick way to ensure the walls stay straight using whatever I could find in that moment. Behold the various things holding it together.

Take the brick out of the mold

There’s nothing sweeter than the smell of freshly cured concrete in the morning. I tore the skeleton apart, and found this beauty underneath. To get the wiring through, holes were drilled in the inner walls.

Did you know it can take up to 20 years for the concrete to fully harden and settle?

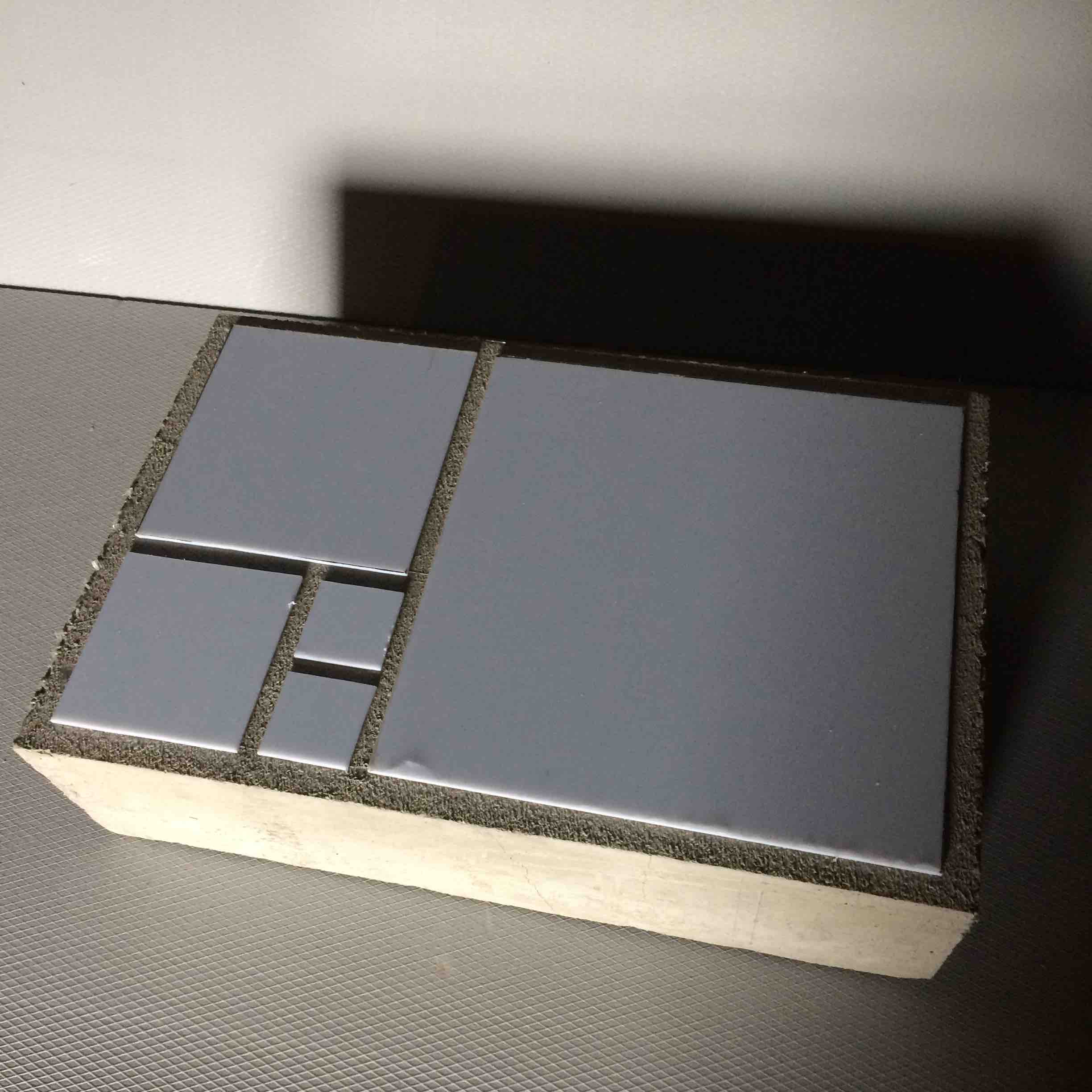

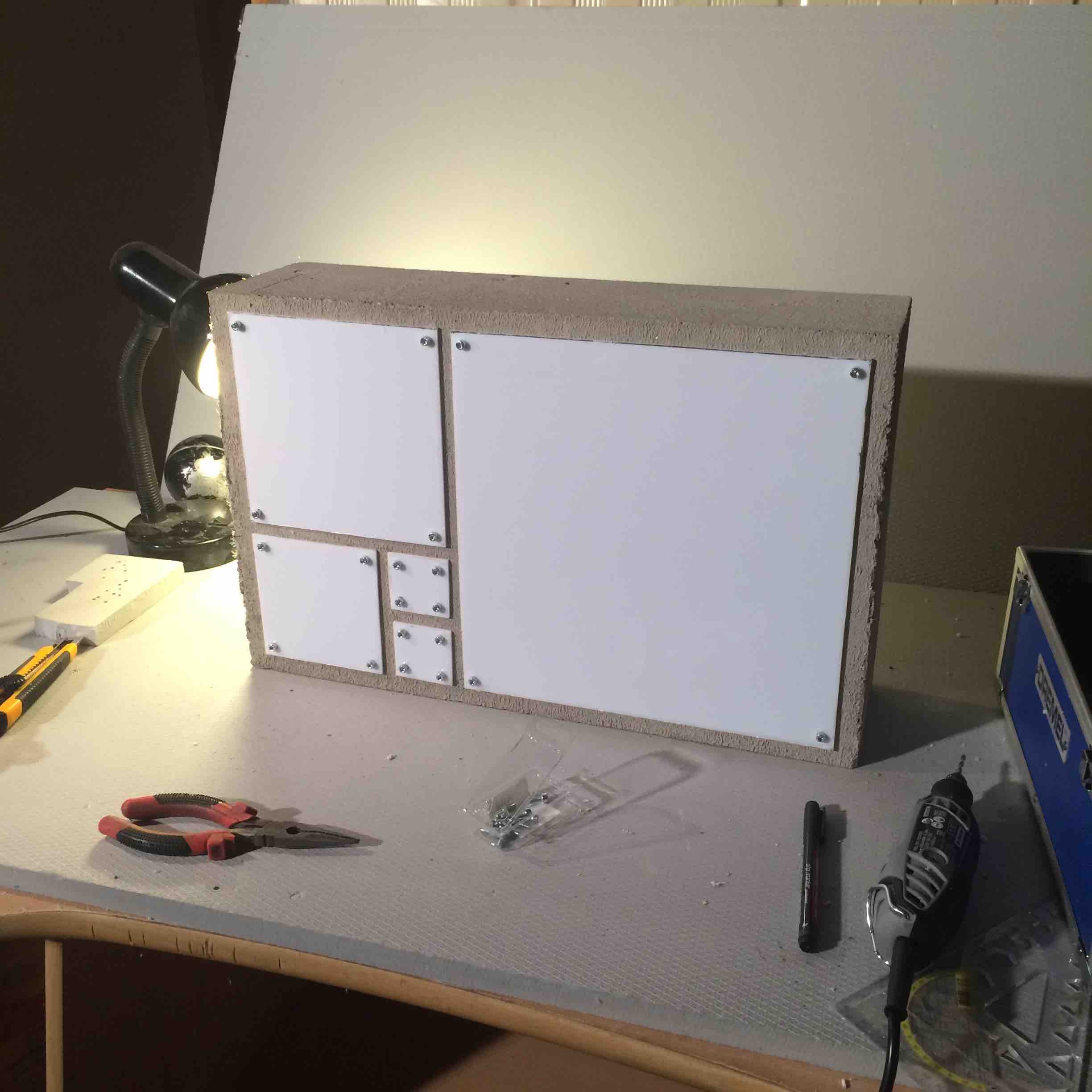

Attach acrylic glass

With a jig saw, I cut the covers out of an acrylic glass sheet, drilled the holes for the bolts and attached the nuts:

Sand and color

Time to sand this sucker down and make it smooth. The amount of dust generated while sanding concrete is colossal and disgusting. The brick was then coated with a protective waterproofer.

Finish up

To project as much light as possible onto the acrylic sheets from the LEDs behind, I made an internal wooden enclosure and covered it with aluminum reflective foil. Let’s also add some legs, so the clock won’t leave scrathes all over the place.

The clock also comes with a secret mode that continuously flashes through a vast spectre of colors. A real feast for the eyes.